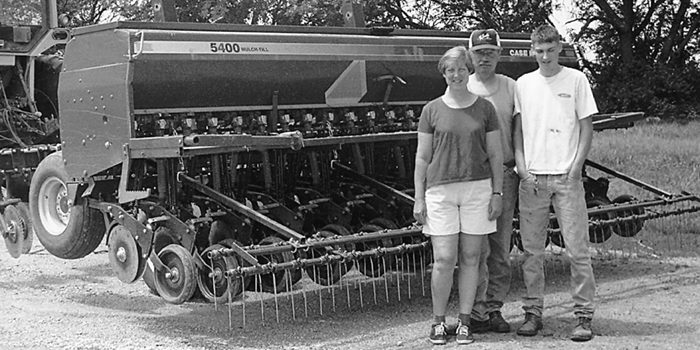

No-tilling at the 1,010-acre Hanke farm in Wahoo, Neb., is a true family affair. While Gary Hanke is planting corn, his wife, Nancy, is drilling soybeans, and son, Mitch, is transporting equipment and also helping drill soybeans.

After experimenting with no-till for 15 years, the Hankes have time management down to a science. However, the road to increased efficiency was paved with some unique challenges.

“We first started dabbling with no-till in 1983,” Gary recalls. “We worked with several chemical companies no-tilling our soybeans into corn stubble using a regular planter. Of course, back then the chemical costs were extremely high...about $50 an acre if you no-tilled without participating in one of the manufacturer’s programs.”

The Hanke’ biggest obstacle was no-tilling into heavy clay soils, especially no-till corn. “This is still a struggle,” Gary admits. “We yield check everything we harvest. Conventional-till corn consistently yielded more. We’ve discovered that making one pass with the field cultivator raises yields 7 to 9 bushels.”

They’ve found it’s best to field cultivate 12 hours ahead of planting to dry the top layer of soil when conditions are wet.

Major Improvements

The addition of a seed monitor to their Case IH 5400 drill and the switch to brush augers on gravity boxes are the biggest improvements the Hankes made to their no-till operation.

“We’re pretty much a low-budget operation,” says Gary. “There’s just the three of us, and my brother-in-law and dad help with combining. It all boils down to efficiency and saving the soil.”

The drill monitor gives the Hankes peace of mind. Previously, they were struggling with the pounds of seed they planted. With the monitor, the Hankes have confidence that seed populations are accurate.

“Before the monitor, I always had to go behind the drill and dig up the seed and count what was being put down,” says Gary. “Back then, we’d always have to be planting corn and beans at the same farm. With the monitor, I can be at one farm planting corn and she can be at another farm drilling beans.”

“I always kept track of how many bags of seed we used,” Nancy adds. “When I’d get done, it was always a lot more seed than what I thought. The drill monitor makes it so much better. I don’t have to be concerned about drilling 275,000 rather than 220,000 soybean seeds per acre .”

“The drill always ends up running out of seed on the ends first,” says Gary. “Some of our neighbors have four to six sensors on their drill. The sensors cost $82 each. You’ll get a better average with more sensors, but it wasn’t worth the extra expense.”

One extra expense that was worth the financial sacrifice was the $750 the family spent to add brush augers to the gravity wagon. Nancy can now fill the drill alone.

“Before, filling the drill was a massive thing,” says Nancy. “I’d have to round up everybody to handle 40 bags of seed. Now, once the auger is set up, I can fill the drill by myself in five rather than 30 minutes.”

Drill Vs. Planting

With Nancy drilling soybeans, the Hankes are able to start planting soybeans the second week of May or when soil temperatures reach 60 degrees. However, they still grow some Roundup Ready soybeans in 15-inch rows.

“I struggle to justify the cost of Roundup Ready soybeans,” says Gary. “We’re drilling 75 to 80 pounds of seed vs. 50 pounds with the planter.

“Our drilled beans usually do better than the row beans, but I think that has more to do with planting date than row width. There’s about a 2-bushel yield advantage.”

The Hankes no-till all of their soybeans because moisture is often a limiting factor. After working the soil with conventional till, the Hankes found they lost valuable soil moisture and yields suffered.

However in 1997, the Hankes planted more acres of soybeans with their White 5100 planter because the soil was too dry.

“Every year is different,” says Nancy. “It doesn’t seem like there’s such a thing as an average year anymore. We intended to drill everything last year, but it was so dry that we had problems finding moisture. We were planting soybeans 2 inches deep to reach moist soil, when normally we set the drill 1 inch deep.”

Harrow Helps

The Hankes have a harrow behind the drill, an attachment that they feel is almost a necessity in clay soils.

”There are times in our clay soil that the seed V just wants to lay open,” says Gary. “This happens when the soil is really wet.

“The harrow covers that seed. At 5 1/2 mph, we get good seed placement and the drill is going fast enough to keep the harrow working and covering the seed.”

Outlining Field

A final helpful hint the Hankes share is outlining fields with a stalk shredder in the fall. This gives Nancy a path to follow when drilling soybeans and it keeps weeds from encroaching into the field.

“Stalk shredding is Mitch’s job,” Gary adds. “He uses a 7- foot shredder for the top of the terraces and a 15-foot shredder to outline the waterways and outside edges.

“This works and it really doesn’t take that long. It also helps me when I spray.”