No-Till Farmer

Get full access NOW to the most comprehensive, powerful and easy-to-use online resource for no-tillage practices. Just one good idea will pay for your subscription hundreds of times over.

“No-till soybeans have caught on a lot faster than no-till corn. We want to close that gap,” says Paul Reed, who no-tills in Washington, Iowa, with his brothers and father.

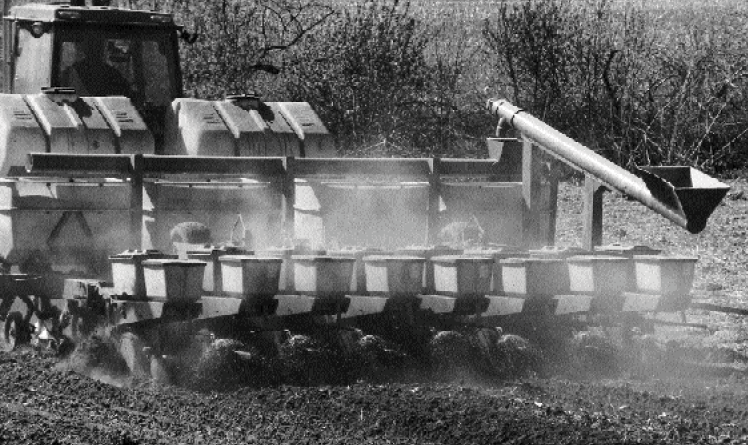

Part of closing the gap, Reed says, is focusing on three problem areas with a big impact on yield and profit:

Increasing no-till planting efficiency through proper row unit set-up.

Understanding and fixing potassium deficiencies.

Knowing which fungicidal seed treatment to use to improve final stand establishment.

Reed says some of the keys to increasing efficiency in a no-till row unit set-up include:

Not being held hostage to the 30-year-old design of the row unit. Fit the row unit to the field, not the field to the row unit as conventional tillage has done in the past.

Raising the row cleaner more than normal to roll on residue in extremely wet conditions. Reed took off his down pressure springs and prefers the face-mounted row cleaner.

Using CaseIH’s beveled gauge wheel tires to lift and blow out the sidewall and prevent roots from being entombed in the seed trench.

Using a twisted drag chain. “It it really evens off that row area so it looks just as good as your neighbor’s, and he’s tilling his whole field,” Reed says. The drag chain also allows the soil to remain more aerated and allows quicker warming in the spring.

Using toothed closing wheels, like Martin spaders, to till behind the row unit instead of in front of it. Loose, dry…