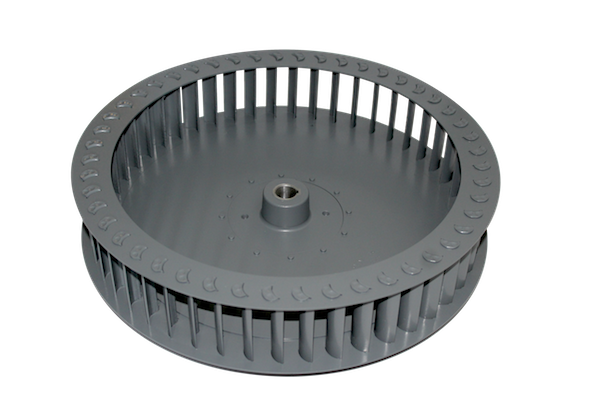

West Fargo, N.D. — Staying on the cutting edge of innovation, Crary Industries has introduced the Infinity Rotor to their well-known fan systems. The Crary Infinity Rotor is engineered for use in any harvest condition and excels in sandy and dusty environments where excessive wear is noticeable on equipment parts.

The new Infinity Rotor extended lifespan has proven triple that of other rotors in both lab and field tests. Crary has raised the bar and subsequently set the new standard of expectation for fan rotors.

“The Infinity Rotor was designed with durability in mind to minimize our customer’s downtime,” said Crary Ag engineer product manager Ben Richard. The Infinity Rotor is engineered and optimized for maximum wear life and air output with detailed design features:

- Fully welded, high strength steel to allow for higher-operating speeds than aluminum rotors.

- Dynamically balanced for high speed performance with minimized vibration.

- Tungsten inert gas (TIG) welded and strategically placed balance clips for increased durability.

- Patent-pending carbide clad inside lower blade edges, designed to increase longevity in specific locations determined by extensive field research of blade wear patterns.

“With a three-time increase in life over standard steel rotors, most customers will eliminate the need to replace a rotor during the lifetime of their fan,” said Richard.

The new Infinity Rotor will also minimize downtime and the need for repeated replacement parts, saving users time and money.