Check out Part 1, which addresses water losses from a center pivot and when to replace an existing sprinkler package.

Sprinkler Package Design

Sprinkler packages should be designed to apply irrigation water uniformly and efficiently while continuing to be feasible. The design must account for characteristics of the specific pivot, the available water supply, and various attributes of the field where the center pivot will be installed. Several factors must be considered, including:

- the capacity of the water source,

- the soils and slopes in the field,

- the tillage practices that will be used,

- the crops to be watered, and

- the amount of irrigation needed each year.

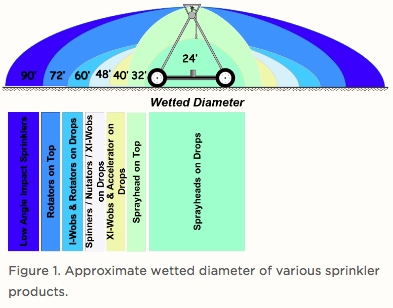

Several design factors must be optimized for suitable designs. These factors include: system capacity, wetted diameter of sprinklers, system operating pressure, sprinkler spacing, cost of the package, sprinkler mounting height, water droplet size and nozzle size. This paper is intended to highlight considerations of in-canopy versus above-canopy sprinkler placement and not describe the entire design process. Refer to the recently published Nebraska Extension Circular Center Pivot Management Handbook (EC3017) for more information on sprinkler package design.

Elements for deliberation in the design include:

- System capacity. The system capacity, i.e., the flow into the pivot, is often limited by the water source; however, if the available flow rate is plentiful, the design needs to determine the required capacity. It is desirable for the capacity to be high enough to quickly irrigate the field, but low enough to prevent runoff. Capacities above six gallons per minute per acre of land (gpm/ac) are usually unnecessary for the High Plains.

- Wetted diameter. The wetted diameter of a sprinkler is the width water is applied by individual sprinklers along the pivot lateral. The wetted diameter is also the distance that water is thrown perpendicular to the pipeline. It should be large enough to prevent runoff across the field when applying the desired depth of water, but as small as possible to reduce evaporation. The recommended water application depth for design is one inch each time the pivot passes. The soil intake rate and slope as well as the capacity of the water source and the length of the pivot are critical factors.

No-till practices can increase the soil intake rate, which reduces runoff potential. Limiting system capacities to 6 gpm/ac will allow selection of application devices with wetted diameters that minimize runoff while using an economical pressure requirement. The wetted diameter can be smaller for low capacity systems (3–4 gpm/ac) or with level fields and no-till production. The system length significantly affects the required wetted diameter. Longer pivots require sprinkler packages with larger wetted diameters at the distal end of the pivot. For help determining the needed wetted diameter for a given system, use the procedure described in Chapters 3 and 4 of the Center Pivot Management Handbook

- System operating pressure and pressure regulators. The operating pressure needs to be high enough to operate the sprinklers correctly based on the design requirements, but as low as possible to minimize energy costs. Pressure regulators need to be used on most systems designed for less than 25 psi. The main exception is when pumping dirty water like livestock waste or water from an open canal that might plug nozzles and regulators. Sometimes in this application, regulators are not used and the pressure is raised to 40 to 60 psi to help move debris through orifices. Good filtration is usually better in these situations because it allows for lower pressures and then requires pressure regulators.

- Sprinkler spacing. Sprinklers need to be spaced close enough to provide good uniformity based on the design criteria, but as wide as possible to lower costs. Sprinkler design software should always be used to determine the best spacing to achieve high uniformity. The smaller the wetted radius, the closer the sprinklers will need to be to achieve high uniformity. When devices are lowered into the crop canopy, the flight of water droplets is obstructed and the wetted diameter of the sprinkler is decreased. The spacing of sprinkler devices along the pipeline must be decreased to maintain uniformity when devices are in the canopy.

- Sprinkler mounting height. Traditional designs place sprinklers high enough to prevent the crop canopy from distorting the spray pattern, but close to the canopy to minimize drift and droplet evaporation. However, some farmers place devices in the canopy in an attempt to minimize water loss from wind drift and evaporation. The wetted diameter of sprinkler devices will decrease when placing sprinklers closer to the ground. In addition, the diameter can greatly decrease when devices are placed in the canopy, leading to poor uniformity and more potential runoff. We discuss this topic in the next section.

- Droplet size. The droplet size should be small enough to avoid crusting the soil, but large enough to minimize wind drift and evaporation. Pivots that do not apply water to bare soils to germinate small-seeded crops can usually utilize sprinklers that produce medium to larger droplets (i.e., drops larger than 0.04 inches), thereby minimizing wind drift and evaporative losses in the air. Droplet size is controlled by sprinkler type, spray plate, and operating pressure. Higher pressures generally produce smaller droplets.

- Nozzle size. Nozzle sizes need to be determined by the sprinkler design software to match the capacity of the water source and sprinkler spacing. Make sure sprinklers are installed in the correct location along the lateral. A pivot can have from 50 to several hundred sprinklers, requiring diligence to ensure they are installed in the correct order and at the right location. Keep in mind that smaller orifices plug easily.