No-Till Farmer

Get full access NOW to the most comprehensive, powerful and easy-to-use online resource for no-tillage practices. Just one good idea will pay for your subscription hundreds of times over.

In the spirit of continuous im-provement, we recently asked strip-tillers if they could provide us with some of the beneficial modifications they’ve made to their strip-till rigs.

Whether it’s a new manufactured strip-till bar or even an older homemade version, the relative “newness” of this management technique means many strip-tillers are looking for ways to improve berm building, fertilizer application or precision performance.

We include several examples here.

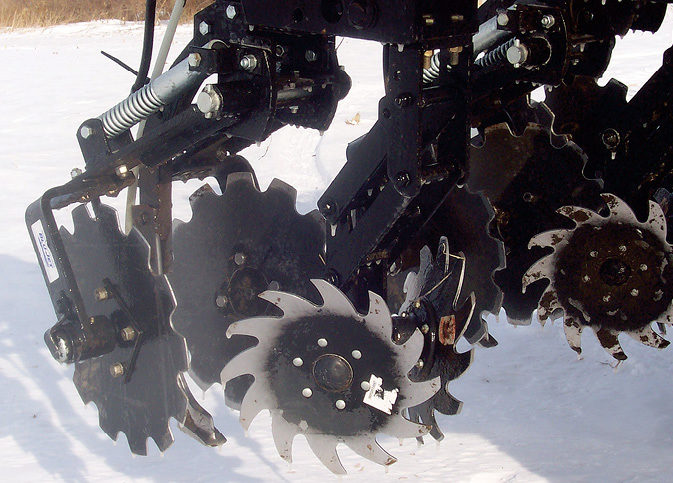

Dean and Ben Fehl of LaPorte, Iowa, recently purchased a Case nutri-till’r 5310 strip-till bar and went right to work making modifications to fit their field operations.

1. “For starters, we did not get the stock Case sealers,” Ben Fehl says. “Instead, we ordered Blu-Jet sealers. There are two arms that act independently, therefore less chance for them to plug.

“A local welding shop helped us fabricate a bracket that moved the sealers forward so that dirt didn’t blow out the sides before it got gathered in by the sealers. This worked very well and we were able to pick up ground speed.

2. The strip-tillers also added Sunco trash wheels. “These work very well and didn’t need any adjustment,” Ben says. “They just float along, moving only the trash out of the way — very little dirt gets moved.”

3. They added a liquid fertilizer tank to ride on the frame.“We have had this in the past, but we had to fabricate brackets to fit this one in place,” Ben says. “A hydraulic-powered pump was added so…