No-Till Farmer

Get full access NOW to the most comprehensive, powerful and easy-to-use online resource for no-tillage practices. Just one good idea will pay for your subscription hundreds of times over.

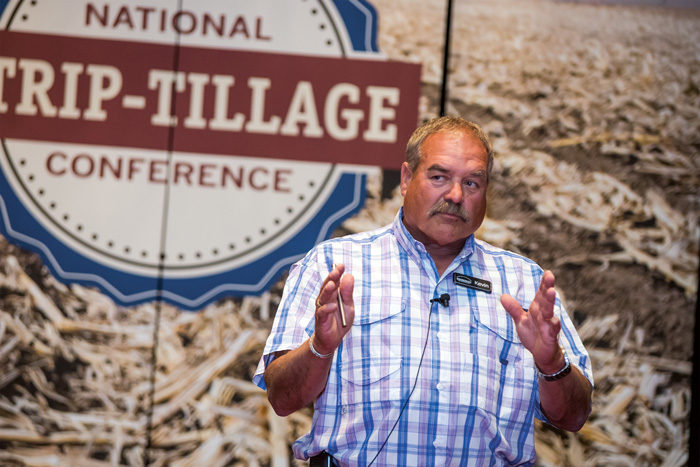

DIAGNOSTIC DIGGING. Crop consultant Kevin Kimberley underlined the importance of digging into the soil behind the planter and strip-till bar. To get a look at sidewall compaction fractures and voids left along the seedbed, his preferred digging depth is about 30 inches.

BUILDING ON the success of the inaugural event last year, the 2nd annual National Strip-Tillage Conference, held recently in Iowa City, Iowa, brought together a diverse group of top strip-tillers, ag consultants and researchers who shared experience-based tips and techniques during some 20 presentations and 30 roundtable discussions.

No-Till Farmer editors have assembled some of the top takeaways for farmers to consider for their strip-till systems, which you’ll find below.

Kevin Kimberley of Kimberley Ag Consulting in Maxwell, Iowa, stressed the importance of strip-tillers letting their soil tell them what it needs — and a strip-tiller’s best friend is a spade.

When digging up a freshly built strip, Kimberley says he’s usually on the lookout for sidewall compaction fractures and voids left along the seedbed. His preferred depth when digging, although it may take some elbow grease, is about 30 inches.

Kimberley also suggests digging up soil behind the planter. When examining seed-to-soil contact and planter downforce, it’s important to cut the furrow down the middle, he says. When looking for the seed, he’s sure to carefully trowel the dirt aside with a flat-edged tool rather than digging for it with a finger.

Often, farmers pack dirt around the seed while looking for it, making…