No-Till Farmer

Get full access NOW to the most comprehensive, powerful and easy-to-use online resource for no-tillage practices. Just one good idea will pay for your subscription hundreds of times over.

A new attachment designed by Agricultural Research Service (ARS) scientists can improve drill performance for growers who want to no-till.

Most drills designed for no-till are not without their share of problems. In heavy residue, plant material lodges on the drill’s furrow opening shank and gets dragged along as the equipment moves forward. Piles of residue up to 4 feet long and 1 foot high can spill over into the adjacent seedbed, smothering seedlings as they try to emerge.

The objective of the new attachment is to develop and evaluate an attachment that would allow a hoe-type no-till drill to handle large amounts of residue and improve drill performance, says Mark Siemens, an agricultural engineer at the ARS Columbia Plateau Conservation Research Center in Pendleton, Ore.

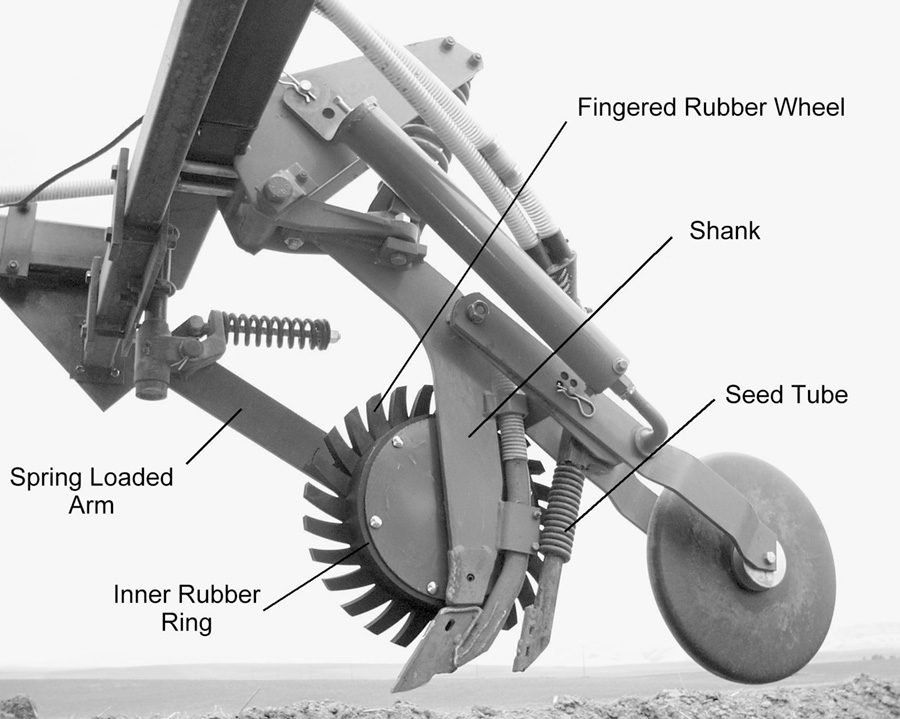

The residue management wheel consists of a fingered rubber wheel, a rubber inner ring and a spring-loaded arm which pivots about a vertical and horizontal axis.

The unit is designed to attach to the toolbar of hoe-type no-till drills and is positioned so the inner ring is approximately 1/2 inch away from the furrow opening shank.

When no-tilling, the ground driven rubber fingered wheel and inner ring hold the unit on the ground and “walk” through crop residue, preventing it from building up on the shank and seed tube. They also help control soil disturbed by the furrow opener so that it stays within the seed row.

When clumps of crop residue build up between the wheel and the shank, the arm…