No-Till Farmer

Get full access NOW to the most comprehensive, powerful and easy-to-use online resource for no-tillage practices. Just one good idea will pay for your subscription hundreds of times over.

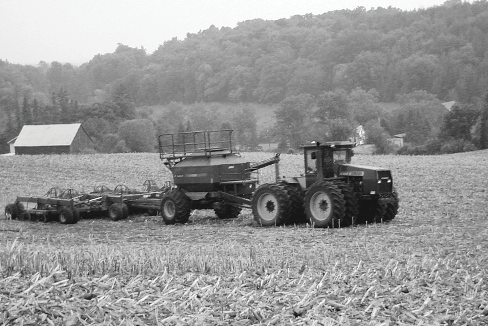

Good business sense plus compassion for their fellow no-till farmers have partnered to create a scattering of custom no-till planting and/or equipment rental enterprises. Here are solid ideas from five entrepreneurs to think about, whether you’re a veteran or novice no-tiller.

You don’t need new no-till planting equipment to do a good job. That’s the philosophy of Jeff Schmitt of Sherrill, Iowa. Schmitt custom plants no-till corn and soybeans, charges $17 per acre, including herbicide application behind the planter, and business is increasing.

He gets “great” seeding depth and uniform germination with a Case IH 955 planter that’s been a workhorse on the Schmitt farm for 20 years. He still pulls the planter with a 2-wheel-drive 8920 Case IH tractor.

“Improving the odds for better seed placement might be an advantage of new Case IH or other modern-day planters over our older 955 models, but we overcome any deficit by slowing down. Other than that, the new row units really haven’t had many radical changes,” Schmitt says.

“I would like to have a 12-row planter, but our fields around here are so small that I’m not sure it would be practical,” he adds.

Schmitt strictly adheres to a planting speed rule of no more than 4.5 miles per hour. “If my schedule would allow it, I would never exceed 4 miles per hour. Everything is just so much better when you slow down.

“We feel that if you don’t plant it right, you might as well…