No-Till Farmer

Get full access NOW to the most comprehensive, powerful and easy-to-use online resource for no-tillage practices. Just one good idea will pay for your subscription hundreds of times over.

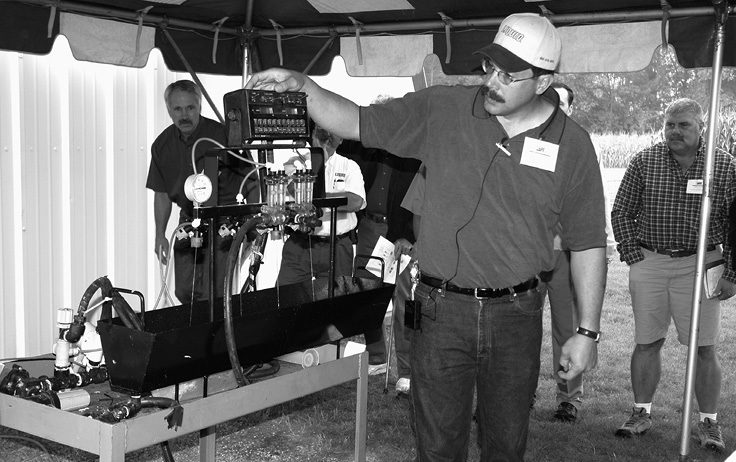

To obtain a more even application rate when using a visual monitor, first increase your sprayer controller speed slightly rather than deciding to replace the nozzles, suggests Doug Summer.

“If a quick change in sprayer speed or AN increase in pressure doesn’t fix the problem, then you’ve got to determine what the real problem is,” says the manager at the Agro-Culture Liquid Fertilizers research farm at St. Johns, Mich.

“It may be a bad tip, a bad filter or a bad orifice. You also need to consider your row widths when selecting spray tips or orifices and make sure that heavy or tall no-till residue is not pulling the hoses away from the spray nozzles.”

When it comes to improving pesticide and fertilizer application, Summer says, remember that increasing sprayer pressure by four times will double the flow rate. However, boosting the pressure will decrease droplet size, increase orifice wear and increase drift concerns.

“Since pressure impacts the spray angle and coverage, be sure that you operate spray nozzles within the proper pressure range,” he says. “You also need to remember that performance data found in most spray nozzle catalogs is normally based on spraying water.

“Since liquid fertilizers are heavier than water, they flow slower. Liquids that are more dense than water, such as 28 percent liquid nitrogen, form smaller spray angles while liquids that are less dense than water will form wider spray angles,” he adds.

Summer says the result is that you should multiply the…