No-Till Farmer

Get full access NOW to the most comprehensive, powerful and easy-to-use online resource for no-tillage practices. Just one good idea will pay for your subscription hundreds of times over.

Research from around the world clearly documents that yield losses occur as a result of equipment passes through the field. Yield reductions occur from either direct damage to the standing crop or from the compacting of the soil, or both.

No-tillers can implement one of two systems to help reduce the impact of wheel traffic and boost their yields and profits. One approach — tramlines — is easy and cheap. The other — controlled traffic — has greater benefits, especially long term, but will take more investment in equipment to implement successfully.

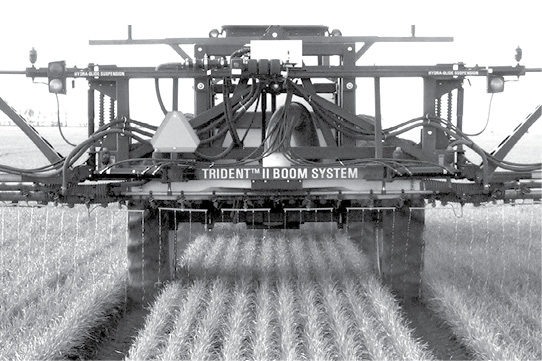

Tramlines are unseeded rows within a field, strategically positioned at seeding to allow application equipment a path on which to drive. Tramlines minimize yield losses compared to knocking the crop down in a standard system, which com-monly reduces yields by 3% to 5%, depending on the wheel and boom widths.

Tramline systems have been used in many European countries for 3 to 4 decades. In fact, most seeding equipment in those countries now comes standard with electronic kits to position tramlines at the correct spacing and the correct travel sequence across the field to match application equipment.

I have helped hundreds of U.S. producers equip their operations with tramlines. When manufacturers don’t offer factory kits, it does take some head scratching and an electronic system to correctly place tramlines within fields. Once installed, however, they are automatic and don’t take any extra time when seeding.

Many innovative producers have GPS lightbars and auto-steer systems on…