How is No-Till Equipment Different?

Requires More Pressure

Conventional equipment is designed to plant into a nicely manicured “fluffy” seedbed. Conversely, in no-till, the ground is firmer and usually covered in a thick residue from the previous year’s crop.

Penetrating the soil and residue requires more down-pressure. This pressure is achieved with more ballast (heavier no-till planters), adding weights on the planters, or by having pneumatic or hydraulic systems on the planters and drills that apply downward pressure.

Requires More Residue Moving & Cutting

Conventional equipment is designed to plant into bare soil. No-till equipment has the added work of making sure the seed can reach the proper depth in the soil. This often involves moving residues to the side or away from the seed trench and adjusting equipment depth settings.

Two Basic Types of No-Till EquipmenT: Drills

No-till drills seed crops in narrow rows. The planting units are staggered to enable residue flow between openers. Drills are typically used to plant legumes, small grains and cover crops.

Planters

Row units on precision planters (sometimes referred to as corn planters) are typically spaced 30-inches apart (On split-row planters, row units may be 15 inches apart.) These planters are designed to plant larger seeded crops and achieve greater accuracy and precision with more consistent solid seeding depth and spacing than drills.

Right Tool for the Right Crops

Some crops, such as soybeans, can be planted effectively with either a drill or a planter, given certain modifications. However, other crops can only be successfully planted with one or the other.

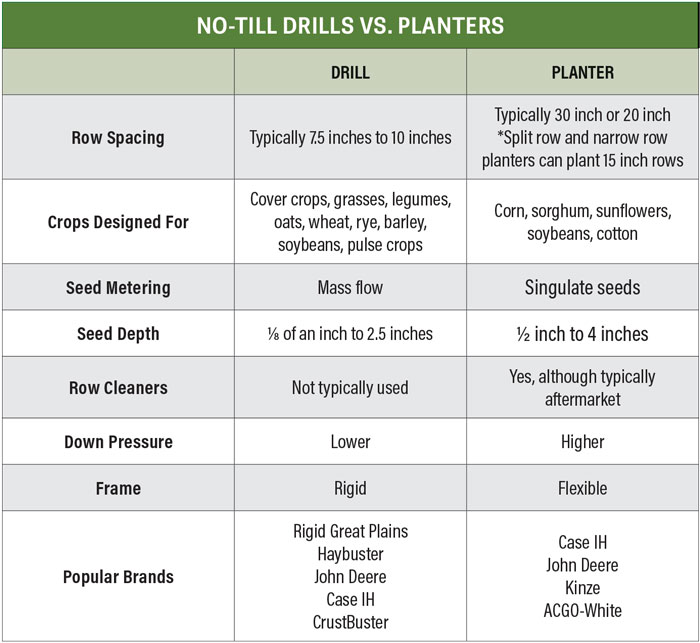

Equipment Comparison: No-Till Drills vs. Planters

Grain drills and planters are complex machines that deliver seeds at a metered rate, place them at a consistent depth in the soil and close the seed trench and produce light compaction to provide good seed to soil contact.

The 2024 No-Till Farmer Operational Benchmark Study surveyed more than 400 no-tillers and showed that 90% use planters on their farm while 58% use drills. About 88% of survey respondents also reported using a 30-inch row width for no-till corn.

Understanding the basic operation of these machines and their strengths and weaknesses is crucial in determining which unit is best suited to meet the desired goals.

No-Till Farmer's "Getting Started With No-Till Farming" is brought to you courtesy of Calmer Corn Heads.

Farmer Invented. Farmer Tested. Farmer Proven.® That motto explains Calmer Corn Heads’ company and state-of-the art corn head technology.

Calmer corn heads not only offers custom-built corn heads, we offer a custom experience. Whether its talking with our experienced sales team or directly with the folks who designed and built your corn head, we are committed to providing you top-notch service without the red tape of a big corporation.

We know Calmer Products work because we run them on our own farms. That’s why we offer a 100% Satisfaction of Your Money Back Guarantee!