- Are similar in construction.

- Have an integrally wound main cable (zero cable) continuously from one side to the other, for strength.

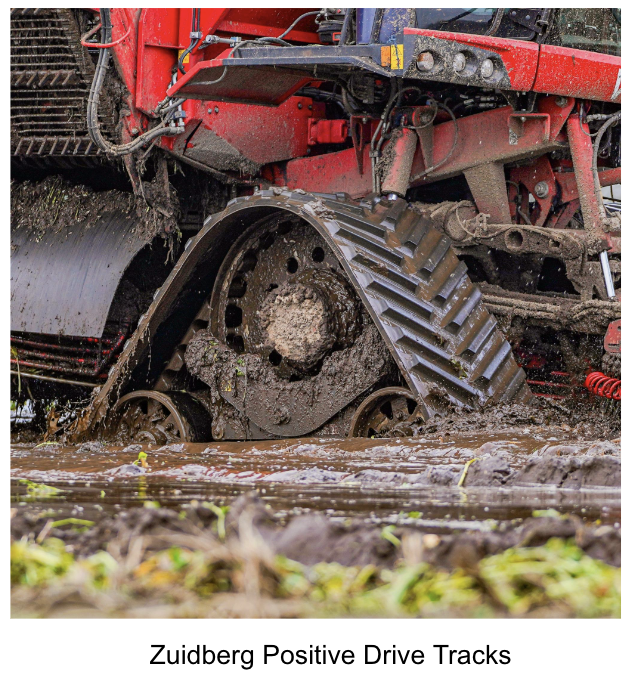

- Rubber outer drive lugs for traction.

- Have a smooth roller path for the wheels to transfer weight of the machine to the ground.

- Have differing layers of steel and synthetic fabrics for strength in different applications.

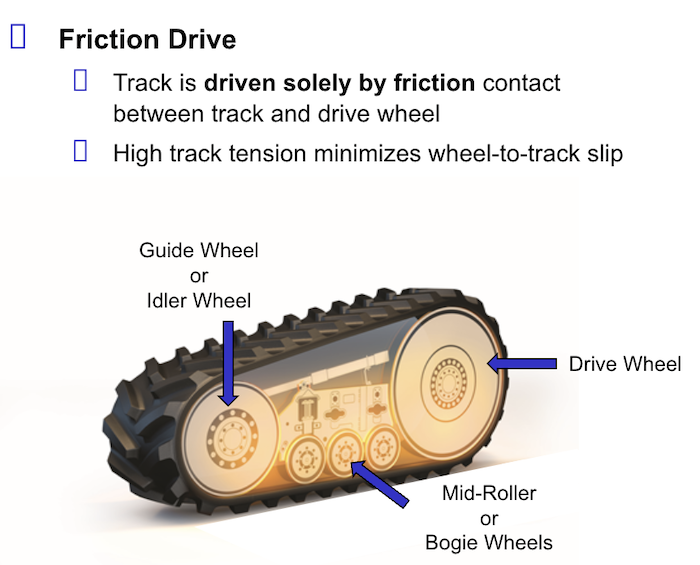

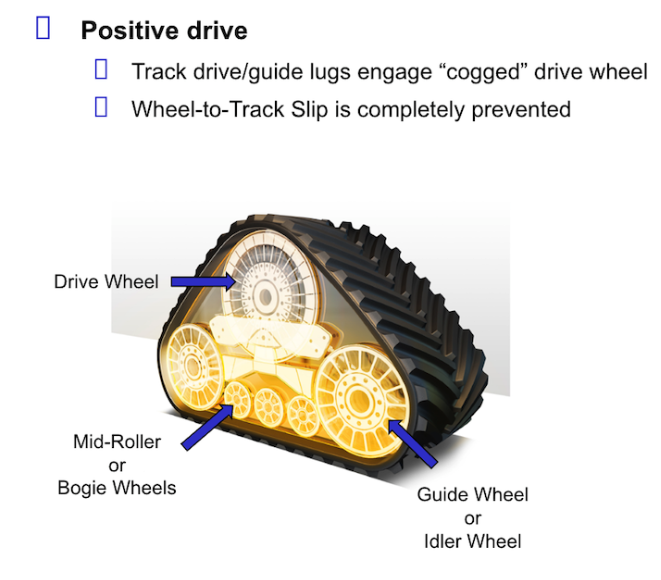

- Friction Drive tracks have Guide Blocks, Positive Drive tracks have Drive Blocks.

- Fairly simple. Two guide wheels, two drive wheels, a track, and bogie wheels to support.

- Typically have less problems with the undercarriage.

- Last much longer as there isn’t as much adverse contact between the components.

- Friction Drive tracks (two tracks) are harder to ballast front to rear with cyclically loaded equipment.

- Friction Drive tracks lose much of its internal traction when moisture levels are too high (mud and/or water) resulting in difficulty maintaining forward direction or steering at times.

- More torque to the ground in difficult or high traction situations.

- Better control maintaining direction and turning in wetter conditions.

- Much lower lifespan than friction drive.

- Typically more problems with the undercarriage.

- Drive lugs are the workhorse of this track. Damage to the drive lugs from alignment, material ingestion, or over pulling greatly diminishes life expectancy of the track.