The originator of the stripper-header was Shelbourne-Reynolds (S-R), based in Suffolk, England. The grain stripper was borne from the picking head on the manufacturer’s self-propelled green-pea harvester, which stripped the green peas instead of cutting them. Applying this technology to a combine harvester was regarded as revolutionary in the late 1980s.

The attachment, which hit the U.K. market in 1989 after a couple of years of R&D, was promoted as ideal for no-tillers wanting to follow wheat with soybeans. It eliminated the scattered windrows of moist, green matter, allowing enhanced seed-to-soil contact when drilling double-crop soybeans in no-till. Because the green weeds were left standing, herbicide efficiency also came. In its first year of production, S-R sold more than 100 units.

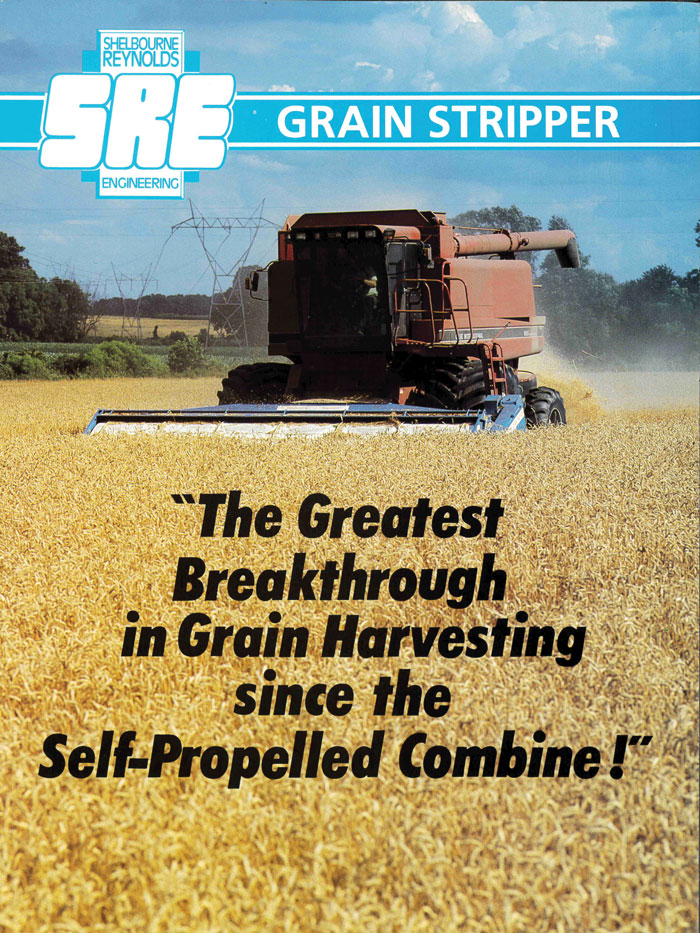

FIRST U.S. MARKETING. Pictured is the 6-page promotional brochure from Shelbourne-Reynolds on the UK-developed stripper-header system. Shelbourne Reynolds

British Invasion

Billy Joe Miles

Image: Miles Family

Neil Smith, a 30-year veteran of S-R, says the first units were sold in the U.S. in 1990. The U.S. story, he says, started with Billy Joe Miles, of Owensboro, Ky.-based Miles Farm Supply (2000 No-Till Innovator of the Year). Miles brought a group of farmers to the U.K.

“They saw the stripper-headers and were immediately intrigued that the machine solved several problems,” Smith says.

Miles was intent on establishing an intensive “European-style” wheat management program back home and wanted to double-crop beans straight behind the wheat.

“The stripper header allowed a faster, earlier wheat harvest at higher moisture without compromising combine efficiency," Smith says. “The stripped standing straw created a more favorable environment to no-till beans due to significantly less hairpinning.”

“According to the 16th Annual No -Till Farmer Operational Benchmark Study, 7.5% of respondents use stripper-headers…”

How It Works

Phil Needham, owner of Needham Ag Technologies in Calhoun, Ky., also had a front-row seat on Miles’s operation. In fact, his friend, Miles, “imported” the British native to the Bluegrass State.

The operation begins with the stripper rotors stripping the grain with chaff and leaves from the straw, Needham says.

“This reduction of material passing through the combine dramatically increased the combine’s forward speed and fuel efficiency,” Needham says. “It allowed farmers to harvest higher-moisture wheat across a longer working day and to dry the grain and get the double-crop soybeans planted sooner. This itself often brought an extra 1 bushel per acre per day in yields.”

DOUBLE-CROPPING IMPROVEMENTS. The stripper-header boosted growers’ ability to double-crop soybeans into the stripped wheat stubble. Image: Phil Needham

Needham says another benefit came with the easier soybean planting conditions through the tall straw, since combines didn’t spread residue well.

“By leaving the wheat straw standing tall, we discovered that the combines didn’t have any chance to screw up the residue spread,” Needham says.

He adds that the tall wheat residue also helped retain moisture during the hot summers and led to higher soybean yields.

Needham says the first stripper-headers on Miles’s Kentucky wheat acres were 20-foot-wide units fitted to Case 1688 combines. He said it was clear that the headers dramatically improved harvesting efficiency for high-yielding wheat.

Corn Yield World Champion’s Family Among First Users of the Stripper-Header

Stanley John Hula Jr.

Image: Hula Family

The first Shelbourne-Reynolds brochure included a name familiar to today’s no-tillers. Virginia farmer Stanley Hula Jr., the late father of 5-time corn yield world record-holder David Hula, shared his experience with the stripper-headers.

“Last year, I burned 3/4 a tank of fuel a day. This year, I cut nearly 5,000 bushels of barley from 10:30 a.m. to 8:30 p.m. with my stripper-header and burned 1/2 a tank. That’s a savings of 25 gallons of fuel a day. 70% of the wheat is thrashed before it ever reaches the combine cylinder. With less trash going through the combine, we wind up with more grain in the tank and less on the ground. And the grain in the tank is cleaner than we’ve ever seen.”

Smith recalls that four farmers on that original tour subsequently ordered — through Miles Farm Supply — the first stripper-headers to touch American soil. Miles imported and distributed stripper-headers through his company Big Rivers Ag Supply, which also sold sprayers and chemicals in Kentucky and adjacent states. Needham says Miles sold hundreds of the units — from Virginia to North Dakota.

Wayne Hunt was among the farmers on that 1986 tour. He now operates H&R Agri-Power (2023 No-Till Farmer Innovator of the Year), a 21-store Case IH dealer group based in Hopkinsville, Ky. The wheat management initiatives started by Hunt and Miles were featured in the Wall Street Journal in “U.S. Farmers Yield to Curiosity About U.K. Wheat Production.”

“Today no-till is a standard practice in our area from start to finish, " Hunt says. “The end result is 3 better crops in 2 years with double cropping, soil building and erosion control.”

The 2024 No-Till History Series is supported by Calmer Corn Heads. For more historical content, including video and multimedia, visit No-TillFarmer.com/HistorySeries.