No-Till Farmer

Get full access NOW to the most comprehensive, powerful and easy-to-use online resource for no-tillage practices. Just one good idea will pay for your subscription hundreds of times over.

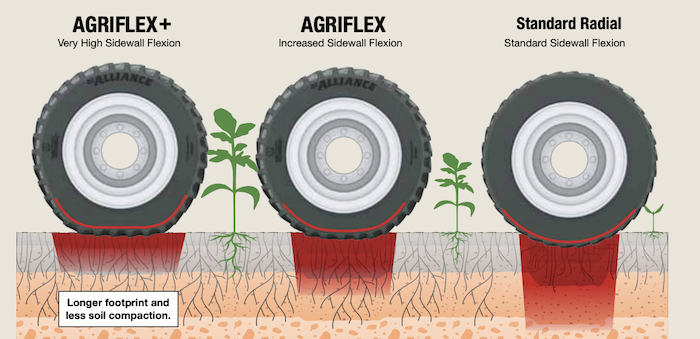

VF (Agriflex+) tires can bear heavier loads and operate at lower inflation pressures than IF (Agriflex) and traditional radial tires. The larger footprint of the VF tire increases traction and minimizes compaction. Photo by: Yokohama

Some amount of compaction is inevitable, even for no-tillers, but there are ways to minimize it by using new technologies developed by the ag tire industry over the past decade.

“If you came to me and said, ‘Minimize compaction on my farm as much as you can,’ I would tell you to go with a VF tire and install a central tire inflation system. That’s the best way,” says James Crouch, national segment manager for Yokohama Off-Highway Tires and self-proclaimed “tire nerd.”

No-tillers can start by aiming for the biggest, most uniform tire footprint possible, Crouch says. But that doesn’t necessarily mean the biggest tires, especially for no-tillers looking to steer clear of certain areas in the field.

“The more uniform the footprint, the lower the compaction because it’s all based on weight divided by square inches,” Crouch says. “But sometimes, depending on your fields, you’re locked into a specific tire size.”

Standard radial tires are better at minimizing compaction than old school bias tires, Crouch says, because they create a more uniform footprint. The weight put on bias tires doesn’t spread evenly across the footprint as much as it does with radial tires.

Certain tread patterns can help alleviate compaction, James Crouch says, largely because of the pattern’s ability to reduce slip in the field.

“Slip does increase compaction because as you’re turning that tire around, you’re putting a lot of pressure on the soil,” Crouch says. “Look for tread patterns that create a happy medium…