Editor’s Note: We asked our friend and de facto no-till historian Tim Brannon to pen a couple of memories of the No-Till Field Day in Milan, Tenn. Here’s his contribution from early June. Brannon had been an Allis-Chalmers (A-C) territory rep in the early 1970s and later became dealer-principal at B&G Equipment, Paris, Tenn. This article is a web continuation of the Milan No-Till Field Day Showed Real World Results that appeared in the August 2022 edition of No-Till Farmer.

— Mike Lessiter, President

Click here if you are having trouble viewing the embedded media player.

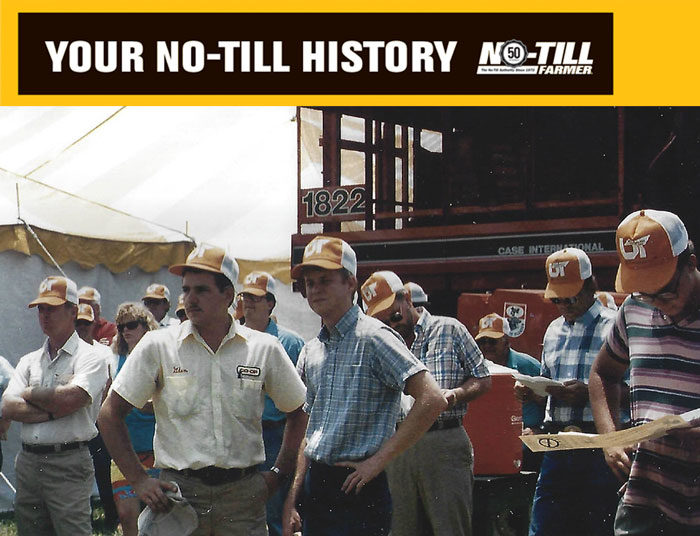

The University of Tennessee’s (UT) “Milan No-Till Field Day” was an event that helped change the methodology of crop and forage production around the world. This annual event started in 1981 after the 1962 formation of the land grant farm that was once part of the Milan Military Arsenal Complex. The land changed from the production and testing of military ordnance to production and testing of agricultural field crops, transitioning to crops grown in a new way – without the plow. No-till research was born.

The shot heard “around the ag world” had just happened on the farm of Harry Young, Jr., in Kentucky’s Christian County in the early 1960s. He and a few others in the area were planting corn and soybeans, without tilling the soil, as had been the practice for centuries. This new no-plow practice was in its infancy and was desperate for research to obtain maximum efficiency, profitability and even “do-ability” of this revolution in ag production. It was going to be a hard sell as change was not in the forefront of the farm community’s vocabulary.

Enter the new UT research facility in Milan. A staff of agronomists, fully dedicated to production of crops in the conventional way, would begin transitioning into planting without disturbing the soil. This shift was not well received at first, but the dedication of a few like the late Dr. Tom McCutchen and Dr. John Bradley persuaded the “powers that be” that this was the future of sustainable agriculture before this term even existed.

This new non-tillage production resulted in conservation of soil as it drastically reduced erosion which had long threatened the viability of the shallow soils of the mid-south. The erosion control demonstration of no-till vs. conventional tillage made news across the nation. The elimination of multiple passes of tillage equipment also decreased crop input costs, manpower requirements and soil compaction. They literally changed the world and paradigms of agriculture as they proved equal to or more profitable and sustainable yields could be achieved in this new production manner.

The No-Till Field Day Routine

The first trips to the “No-Till Field Day” doesn't seem to have been 40 years ago, but I do remember it was always held on the hottest day of the year or at least that's what we thought.

Upon arrival, you noticed the parking stalls and traffic alleys were marked off in a wheat field with single rows of no-till soybeans. After signing in, you had to choose which of the many tours to attend if not all – and it would turn out to be an all-day affair.

Then, a slew of wagons with straw bales for seats carried you off to various stops where a waiting UT agronomist or professor would be standing under a small tent. Each would explain the tests conducted and proceed to flip over the large charts on an easel and, with a 3-foot-long pointer, summarize the results of the plot as to crop, fertilizer, chemicals, yields and other factors. And they sweated profusely throughout the day.

The favorite spot on the tour for most was the “bottom” field where manufacturers of early no-till (“No-Til” was an A-C trademark) planters demonstrated their attempts of no-till planting in the brick-hard, July-baked, clay soils of Tennessee. At first there were just a few: A-C, Buffalo, John Deere, International Harvester, Great Plains, Tye and some others. As the years went by, there were as many as 25 or more planters and drills in the field. There were hooded sprayers and even no-till cultivators being demonstrated – everyone always scratched their heads as to this endeavor, which seemed an oxymoron.

Spra-Coupe Shined

The big winner in the first Field Day demonstrations had nothing to do with planters – it was Spra-Coupe. They had their little sprayer that looked like a small plane without wings running all over the field at what seemed like 100 mph with the operator smoothly riding in the cab with the suspension taking all the abuse. Farmers were thinking, “if that thing can do a good job running that fast, I could spray the whole farm in a day!”

Spra-Coupe Self Propelled Sprayer

Volunteered to Volunteer

Working for the A-C farm equipment company in the 1970s and being a Tennessee “Volunteer,” I was “volunteered” to display our wares for several years even before the “Field Days.” Willis Mussleman was the A-C district director and was always trying to get product in and on the experiment station grounds, from the planters to tractors to pull the tour wagons.

We were sent to Milan for a week one spring for the assembly and set-up of a no-till planter to plant corn and soybeans in “concrete.” We learned how to hydrate, again before that was a “word.” We were tasked with setting up the “erector set” that was the A-C 600 series planter, complete with No-Til coulters, flat chain units, insecticide/herbicide attachments and whatever else was in the price book.

By noon each day, the metal of the planter reached around 700 degrees by our estimation and required a siesta. One day, a “real” plant engineer actually showed up (we had no idea who he was) and informed us the chains were on “backwards.” My cohort rookie told him something about what he could do with those chains. It resulted in a lengthy report and reprimand.

Extra Effort Needed for Tough Conditions

Anyway, we were charged with winning the hearts and minds of the staff as to planting no-till soybeans and covering them better than the competition. We soon found we needed weight to do this. Since the advertising stated we had the heaviest frame on the market, adding hang-on weight was not allowed, nor did we have a factory bracket to do so. A trip to the local scrap metal yard led to the discovery of lengths of 3-inch solid round bar stock that could be slipped inside the three 3.5-inch diagonal frame bars. That did the trick, and no one was the wiser. We were just careful to go slow to avoid the loudest clanging sound ever heard. They served us well for years until the models changed.

This, with the late-night precision-sharpening of coulters and openers yielded us the ability to plant the field with success where others failed. A part of the early planter is displayed in the Museum that is a part of the Milan research center today.

AC No-Till Planter

An Inconvenient Visit

Later in 2000, our dealership was helping with the AGCO display on tour day. Al Gore was running for president and some campaign genius decided it would be a great idea for him to visit the Field Day. The Secret Service had all the power units and engines shut off while a passel of attendees lined up to shake the hand of the man who would wind up not being president (and didn't even carry his home state of Tennessee).

We did not want to stand in that line, and I knew the guys in the field were thirsty, so we knew a back way to deliver refreshments. About 300 yards into the journey via a back road, a Secret Service agent stepped out of a thicket and instructed me to shut off my engine. I stuck my head out the truck window and attempted to explain I was headed away from the candidate and that our men were thirsty. The agent leaned over, exposed a huge weapon under the vest and stated “Sir, either you will shut that engine off, or I will do it for you.” I handed him the keys and dragged the cooler behind me for a half mile.

Later, I was the last person to shake ole Al's hand and told him sarcastically that we were certainly glad he chose to come to the Field Day. He didn't pick up on the sarcasm and thanked me with a faraway look in the eye as he was whisked off, thankfully for us, from the Field Day.

Cotton-Pickin’ Politics

One of the largest and most radical ideas of the Milan no-till program was ultra-narrow row, no-till, Roundup Ready, stripper cotton. We provided a White 6800, central-fill planter to the UT program for 15-inch no-till cotton. Planting on 15-inch rows required using a cotton stripper in lieu of a cotton picker. The stripper featured a tremendous advantage in the production process:

- Less initial cost (about two-thirds less).

- Tremendously less upkeep and parts and labor costs.

- A cotton stripper would last almost forever.

John Deere furnished a stripper equipped with an old A-C finger stripper head adapted to it. Everything seemed on track until one early spring day I called down to the research center to see if they needed the planter another year and asked for Dr. Bradley, who was the head of the cotton project. I was shocked to hear Dr. Bradley was no longer employed there.

I inquired about the planter and was told it was no longer needed. I asked about the cotton stripper and was told the program was canceled and the green picker was gone. I found out later that Deere and possibly IH had contributed big bucks for them to work on a new super-staple picker cotton variety.

I guess the light bulb came on. A million-dollar, short life picker with big bucks’ upkeep vs. a quarter-million-dollar stripper with almost no upkeep. Deere and Case would have been shooting themselves in the foot or other parts of the anatomy to buy into a program built around machines that made them little money vs. the mighty cotton picker and losing billions in opportunity costs in parts and labor down through the years.

Dr. Bradley (who became known as the father of no-till cotton) actually grew narrow row stripper, Roundup-Ready cotton in a fescue field on his own farm. Recently, I asked Dr. Bradley what happened to the stripper cotton program he’d put so much effort into. The answer was the cotton gins just would not “'get on board” and agree to put in a simple stick machine or endorse a stripper-harvested product. Later, when Deere got the bugs worked out of the baler/picker, the gins gladly invested millions in round bale handling equipment as Deere monopolized the cotton harvesting market.

Today the research center has switched to bi-annual tours and programs on site at the end of July. It is still worth the battle with the July heat there, although Al Gore might say it is “inconvenient.”

RELATED CONTENT: Click on these 2 links for No-Till Farmer's podcast and video interview with Blake Brown, who heads the University of Tennessee AgResearch & Education Center & No-Till Field Day.

Tough Conditions to Prove No-Till

“One thing I remember was how surprised people were that we could plant into wheat straw without a no-till coulter. The first year we demoed, I pulled a 4 row JD7000 125 miles from Elkton to Milan and we borrowed a tractor to pull it with. It's a miracle that I didn't blow a tire or have a wheel bearing failure on those first couple of trips before we had a trailer to transport the 4-row on. The planter had no coulters, just row cleaners. We had added sand to the dry fertilizer boxes to gain enough ballast for the heavy duty, downpressure springs to keep the row unit in the ground. We usually ran beside the Kinze dealer who had a Twin Line with coulters – people just assumed you had to have a coulter. Demoing at Milan all those years played a key role in our row cleaner sales for double-crop planted beans. In later years, we added the C125 row cleaner to work with the coulter.”

— Steve Martin, Martin Industries, Elkton, Ky.

GRASSROOTS GROWTH. Great Plains founder Roy Applequist holds the original grain drill model he constructed after asking 100 central Kansas farmers what they needed.

The Milan No-Till Field Day in Tennessee got its start in 1981, and Great Plains and a few other drill manufacturers were there for the second year in 1982 with several no-till prototype drills. It was really hot, the bees were stinging, and the drill competitors ended up in the hotel swimming pool that night to cool off.

Lots of narrow-row soybeans were grown in those days, and narrow-row soybean drills were selling well. As no-till kept growing, we developed a flexible center pivot hitch with the coulters in front of the drill to handle tracking on curves and terraces.

Most competitors offered rigid coulters that didn’t track the opener properly when you turned, but our tracking feature sold over 10,000 machines for us over the years.

– Roy Applequist, retired founder of Great Plains Mfg., Salina, Kan.

GOT YOUR OWN MEMORIES OF THE MILAN NO-TILL FIELD DAY SINCE ITS BEGINNING IN 1981? ADD IT TO THE COMMENT FIELD BELOW ...

The 2024 No-Till History Series is supported by Calmer Corn Heads. For more historical content, including video and multimedia, visit No-TillFarmer.com/HistorySeries.