Over his storied life of developing iconic performance vehicles, the late Caroll Shelby was often quoted saying: “There is never enough horsepower … just not enough traction.”

I doubt the developer of the famous 427 Cobra and Le Mans-winning “GT-40 Fords” has been on the minds of engineers developing tires for tractors and combines, but those engineers’ efforts over the past 20 years are on target to address Shelby’s concerns.

Importance of Psi

The ag media is replete with studies showing the positive relationship between lower tractor and combine tire pressures and overall corn and soybean yields due to reduced field compaction. Research shows lower farm equipment tire pressure equates to less compaction, and less compaction correlates with higher yields. But that’s only part of the story. Improved traction provided by tires capable of operating at lower inflation pressures is finally making some headlines on its own.

In “Deep Dive Into Advanced Tire Technology,” Lessiter Media’s recently published special management report No. 76, the improved traction of lower-pressure tractor tires was linked to estimates of fuel savings of more than 50 gallons of diesel over a 1,000-acre field in a recent field comparison conducted by Firestone Ag.

“The tractor with lower tire inflation pressure was more than 50 feet ahead of the other tractor……”

The test involved a pair of identical test tractors with identical standard tires connected by a cable and pulley system to a third “load tractor” (not running) equipped with a 23-foot field cultivator. The only variable for the test tractors was tire inflation — 15 psi for tractor and 30 psi for the other.

“As the tractors moved down the 1,000-foot test course, the tractor with lower tire pressure and larger ground footprint was able to pull ahead of the tractor inflated at near maximum pressure,” says Dusty Hininger, field training manager for Firestone Ag. “At the end of the course, the tractor with lower tire inflation pressure was more than 50 feet ahead of the other tractor.”

Hininger says lower tire air pressure was responsible for the difference in traction — a difference that can add up to increased productivity in several ways.

With both tractors moving at 6 mph, he says the properly inflated tractor can cover 16.73 acres per hour, compared with the over-inflated tractor covering only 15.89 acres.

“Over 1,000 acres of tillage, the difference amounts to more than 50 gallons of diesel burned by the over-inflated tractor, compared with the machine running lower tire pressures,” Hininger says. “Also, because of better traction and additional ground covered, the tractor with lower-pressure tires will finish its job 3 hours and 15 minutes ahead of the other tractor.”

Hininger says the simple practice of reducing tire air pressure during field work can equate to more than $226 in fuel savings with $4.50 diesel and more than $63 per hour in operator time, based on a $20 per hour rate.

The test was repeated comparing standard tires with high-flexion tires, which enable growers to significantly further reduce operating tire pressure. That comparison yielded even more time and fuel savings from the larger footprint available through the tires with flexion technology.

The in-field demonstrations are consistent with recent studies at Harper Adams University in the United Kingdom. The results show adoption of properly inflated VF tires produces less slippage, which improves productivity and results in fuel consumption savings of roughly 10%.

HEAVY SEEDING. This is 1 of 5 new John Deere 9R 640 tractors on the Sunny Dale Hutterite Colony rigged for seeding this season near Arelee, Sask. Colony management equipped their purchases with LSW 1400 singles and reported fuel savings of at least 30% compared to a similar dual-equipped tractor operating in the same fields.

A Real-World Comparison

We recently visited with Pat Newton, owner of Saskatchewan Saskatoon Wholesale Tire and a cooperator with U.S.-based Titan Tire Corp. in its development of the LSW (low sidewall) 1400 “super single” ag tires in the prairie province known for its small grain production. He says large growers there have noticed significant reductions in fuel consumption and improved productivity when compared with identical tractors equipped with duals or tracks.

“Last year, the Sunny Dale Hutterite Colony at Arelee, Sask., ordered 5 new John Deere 2324 9R 640-hp tractors and had them equipped with LSW 1400 singles and Titan wheels,” Newton says. “They had experience with the technology over several years working with our dealership and Titan as we developed the tire. They were so impressed that they equipped their new machines with LSW traction before they were delivered. They already had an identical tractor equipped with 800 duals, which they used in performance comparisons with the new machines equipped with singles.”

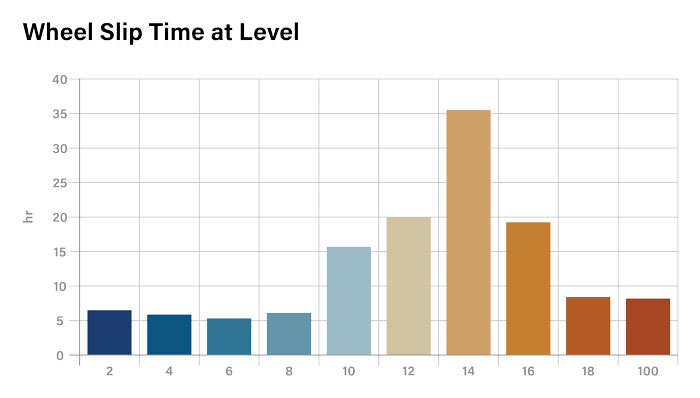

DUAL EQUIPPED. Wheel slippage measured through 2 weeks of seeding with a John Deere 9R 640 pulling a 76-foot drill and C850 seed cart on flat fields showed a peak of nearly 35% with three intervals at 15% or higher.

During seeding for the 2024 season, tractor operators at the colony kept track of wheel-slip and fuel consumption monitors as they pulled an 84-foot air seeder and a 1,200-bushel cart. Running 20 psi in front and 12 psi in the rear, they recorded 8-12% slippage. With front inflation at 15 psi and rear at 12 psi, slippage dropped to 3-4%.

“Data from the tractors during seeding showed cost of fuel per acre dropped significantly when compared with the identical tractor pulling the same load only equipped with factory 800 duals,” Newton says. “The worst case showed a 30% savings on fuel.”

“The LSW tires showed less than half the slippage as the dual-equipped machine……”

In southern Saskatchawan near Radville, Toby Torkellson compared field performance of his John Deere 590R equipped with LSW 1400 singles and a neighbor’s Deere 9R 640 equipped with standard duals while seeding about 450 acres of lentils.

Torkellson’s land includes some rolling fields, while the neighbor operates primarily on flat fields. The neighbor pulled a 76-foot drill. Torkellson was hitched to a 70-foot seeder. Both setups included a Deere C850 seed cart. Wheel slippage reports measured on each tractor’s monitor over the first 2 weeks of seeding were pulled at the same time by the local John Deere dealer for comparison.

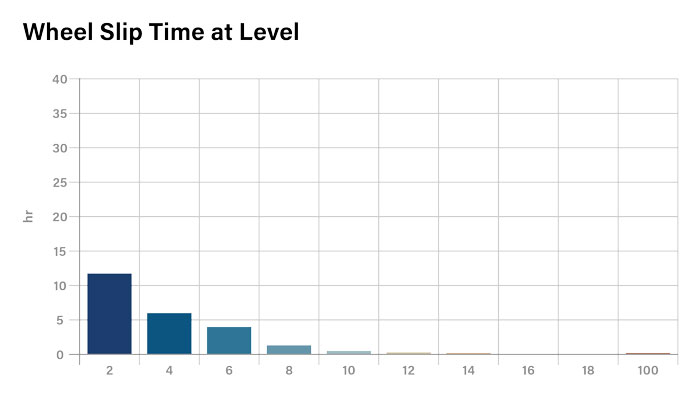

“We were extremely impressed with the increased traction and reduced slippage compared with our neighbor’s machine on duals,” Torkellson says. “The LSW tires showed less than half the slippage as the dual-equipped machine, and we found our drill speed was nearly identical to the tractor speed, showing 1% slippage quite often (see graphs).

LSW SINGLES. Maximum wheel slippage measured with LSW 1400 tires on Torkellson’s 590R, pulling a 70-foot drill and C850 seed cart over rolling fields, measured slightly over 11%. All other samples through the period remained at 6% or lower.

“It was an expensive experiment to spend my own money to replace my duals, but the results far exceeded my expectations. I also noticed the tractor rode much smoother than before.”

Morry Taylor, board chairman of Titan International and developer of the firm’s LSW technology, says as horsepower on the North American farm increased from under 100 hp tractors to today’s 600+ hp machines, growers needed to find ways to optimize. That brought about extensive use of duals and triples.

“We’re seeing now that we can compete with duals and tracks with properly designed wide singles because of their flexible ability to increase tire footprint with lower inflation pressures,” Taylor says.

While he likely never dealt with 46-inch rims or 48-inch-wide tires, Carroll Shelby would probably agree modern ag tire designers are on the right track.

Post a comment

Report Abusive Comment